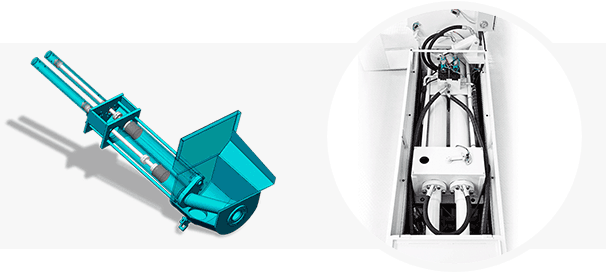

Even the name represents progress — the BT Pump is yet another proof of EVOMAQ®’s continuous pursuit of improvement. This equipment was designed with the main purpose of reducing the operational costs of EVOMAQ® customers, as it eliminates the need for at least one truck and all associated operating expenses.

Keeping the equipment clean is the first step toward proper operation and long service life. For that reason, the EVOMAQ® pump’s water tank features a powerful pressurization system, which makes cleaning and equipment preservation easier.

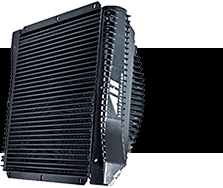

An efficient cooling system stabilizes the oil temperature, maintaining proper viscosity and preventing premature wear of the hydraulic system.

The exclusive pipe support system is designed to organize the work platform, keeping all pipes properly arranged and secured.

The rounded hopper design simplifies cleaning and helps direct concrete more efficiently into the delivery cylinders, increasing pumping performance.

The hopper cleaning valve also stands out with its exclusive lever system, allowing it to be opened from the side of the machine, making cleaning and maintenance even easier.

All EVOMAQ® equipment comes equipped with a powerful hydraulic mixer, ensuring that the concrete remains properly mixed between loads.

The optimized pumping system reduces the number of components, resulting in greater productivity and lower maintenance costs.

An efficient cooler system stabilizes oil temperature, keeping it properly viscous and preventing early hydraulic wear.

The EVOMAQ® pump’s electrical system stands out for its simple design, making operation easier and eliminating relays and timers by using a limit switch instead — once again resulting in lower maintenance costs.

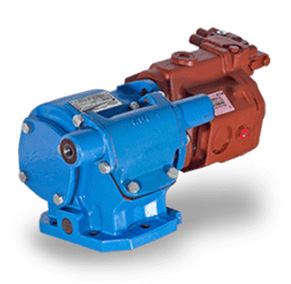

As with several other types of construction equipment — such as concrete mixers and boom pumps — the EVOMAQ® pumps are designed to utilize the truck’s own engine, offering reliability and durability without compromising efficiency, even under extreme conditions.

This design also allows a reduction in the total investment cost.

| Model | 1560 SIDE MOUNT | 1560 REAR MOUNT |

|---|---|---|

| Maximum Theoretical Output (m³/h) | 40 | 38 * |

| Cycles per Minute | 24 | 44 * |

| Maximum pressure on theoretical concrete (bar) | 65 | 65 |

| Cylinder Diameter (mm) | 90/63 | 90/45 |

| Maximum Aggregate Size (mm) | 25 | 25 |

| Cylinder Stroke (mm) | 1000 | 560 |

| Delivery Cylinder Diameter (mm) | 180 | 180 |

| Concrete Volume per Stroke (liters) | 25,45 | 14,25 |

| Type of Diverter Valve | "S" | "S" |

| Horizontal Pumping Distance (m) | 280 | 280 |

| Vertical Pumping Distance (m) | 45 | 45 |

| Weight with Power Take-Off (kg) | 850 | 850 |

* Depends on the truck / power take-off

This website uses cookies and similar technologies and by continuing to browse you agree to the terms of our Privacy Policy.

X